Complete filling line for dips or any other hot or cold thick-sticky products in tubs, cups, pails or clamshell containers

Adapted filling line for semi-viscous products like cheese dips, hummus, margarine, muffin dough, chocolate syrup, caramel, salsa, etc.

For these we have developed:

- Several containers’ distributors adapted to work well with many different shapes of tubs/cups or pails with or without handle. We can also distribute clamshell containers.

- Several lids’ distributors adapted to work well with many different lid shapes apply to tamper-evident or sealable containers.

- A closing head with an optional air removing system ensuring that the lid of a tamper-evident container is pushed in while closing it to make sure it looks concave.

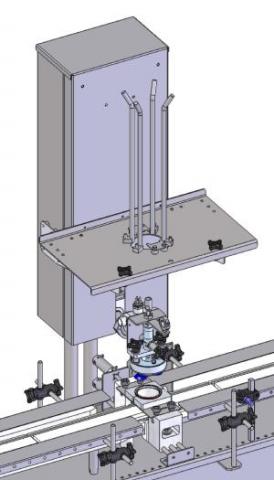

- A wide variety of volumetric piston depositors/depositors of different capacities allowing us to fill either your base products or small quantity of garnishes. These can be either pneumatically or electrically driven via a servomotor.

- A volumetric piston depositor with a compensation chamber for products like margarine, melted chocolate and glue, which is connected directly to a pump allowing us to push your product in the volumetric chamber. This system increases the filling accuracy for such thick products. We can jacket some or all components of the depositor’s chambers and piping to keep the product hot when it is required.

- Many different styles of dispensing valves adapted to the texture of various products. These can be mounted on a vertical movement pneumatically or electrically driven via a servomotor.

- Containers vibrators to evenly spread the product.

- A time-based spice sprinkler.

Our standard filling lines can also be equipped with an automatic sealing unit, with or without gas injection for Modified Atmosphere Packaging (MAP). The seal quality of our sealing system allows our customers to also use High Pressure Processing (HPP).

Adapted Equipment

Additional Modules

Additional Modules for Filling Lines for Viscous Products

For fully integrated filling lines:

- Automatic cup, tub, tray and buckets plastic film sealer: the PL500

- For the multi-lane filling lines, a lane concentrator may be required,

- Transfer pump to feed our depositor: the PV2000

For small production: stand alone components can be proposed (please visit our Machine Guide), such as, for example :

- a container denester DS1500,

- a container closer FS1500

- a lid denester and closer FDS1400,

- a filling position plus a lid denester and closer: the FDS1500,

- or an accumulation table T50

English

English

Français

Français