Specific Devices

Here you can see types of our Cup Filling Machine for Sticky Products:

- The “tunnel”: for a liquid sticky product, we developed an anti-splashing plate which integrates an air-vented dispensing valve, that will prevent any splashing during the high speed filling phase, and, when the filling cycle is finished, that will make the containers lips scrape the under-side of the tunnel , thus cleaning the plate. As a result, there is no need to wait for the last drop of product, which can be very long with sticky products, and the container is always kept clean. This allows us to reach a speed up to 40 1 lb CUPS/MINUTE on a SINGLE LANE machine.

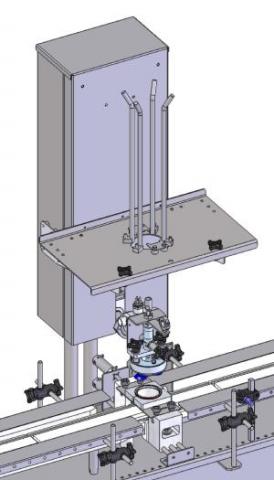

- Bottom fill dispensing valve : this may be best adapted for sticky and viscous products, with a big size dispensing valve diameter (from 2″ to 3″) : for up to 60 1 lb TUBS/MINUTE on a SINGLE LANE machine.

Adapted Equipment

Additional Modules

Additional Modules for cup filling machine for sticky products

For fully integrated filling lines:

- Automatic cup, tub, tray and bucket plastic film sealer: the PL500

- For the multi-lane filling lines, a lane concentrator may be required,

- Transfer pump to feed our depositor: the PV2000

For small production: stand alone components can be proposed (please visit our Machine Guide), such as, for example :

- a container denester DS1500,

- a container or pail closer FS1500 or FS1800

- a lid denester and closer FDS1400,

- a filling position plus a lid denester and closer: the FDS1500, or an accumulation table T50.

English

English

Français

Français