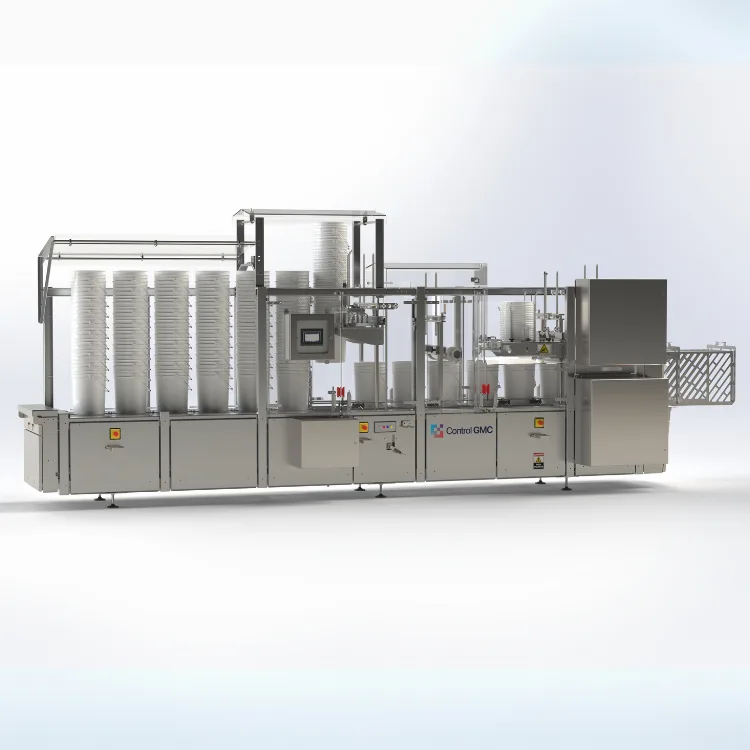

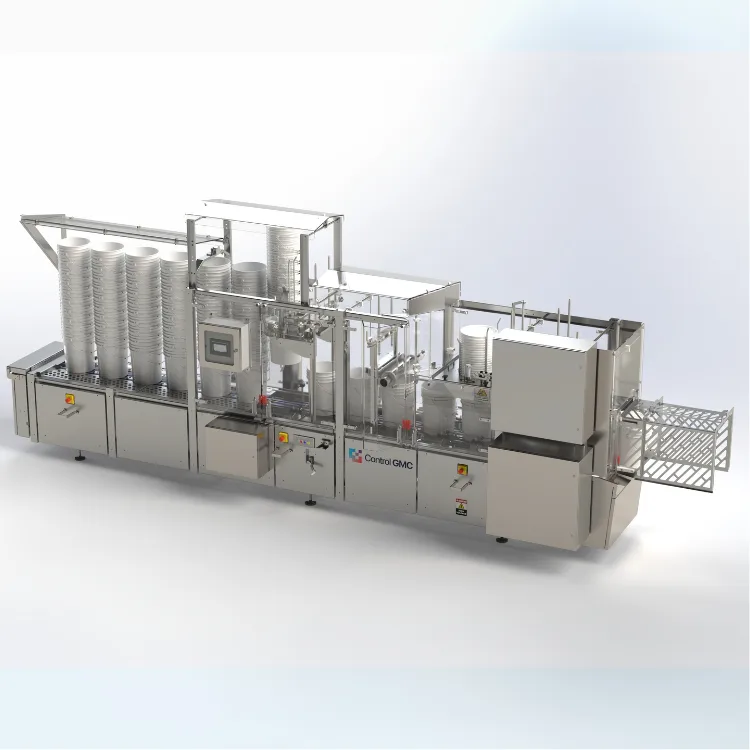

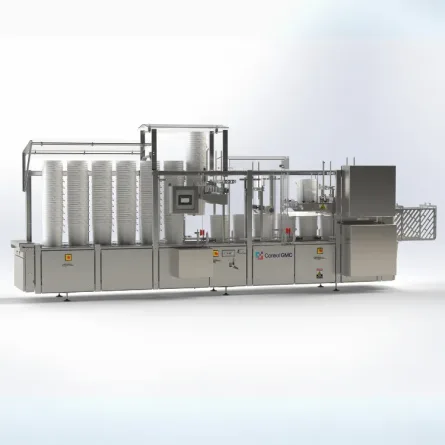

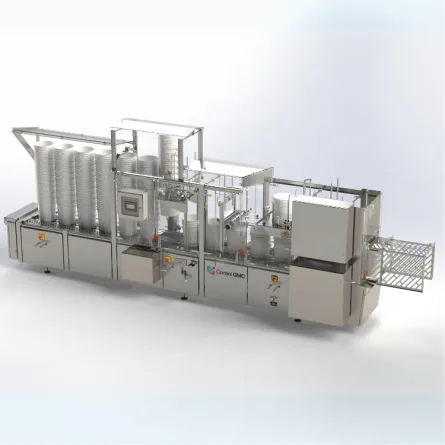

FDS3500 Pail & Bucket Filling Machine

The FDS3500 is a versatile automatic Pail & Bucket Filling Machine for food or chemical products in large size containers (Up to 6 gallons ). It feature a high autonomy system allowing the operator to deposit up to ten stacks of empthy containers on the indexing conveyor which automatically feed them one at a time in the one by one container distribution system. It handles plastic pails, tubs, or buckets with or without handles. The indexing conveyor also incorporate as many filling stations as required , a one by one lid distribution system along with a closing tool. If required, we can install a high autonomy lid distributor.

The FDS3500 can manage:

- Any Shape and Material of Containers:

Capable of filling round, square, or oval containers in multiple materials such as plastic, paperboard, and aluminum, meeting the diverse packaging needs of different industries. - Any Size of Containers:

Food service containers.Ideal for filling and packaging large size containers such as plastic pails, tubs, or buckets. - Tamper-Evident & Non-Tamper-Evident Containers:

The system can fill and close containers with or without tamper-evident features, ensuring secure and reliable packaging. - Many Different Products:

Suitable for liquid, dry, viscous, or sticky products, making it highly adaptable for various industries, including food, chemicals, and more.

We design and build custom-made machines tailored to your specific needs.

Whether you require a unique configuration, special features, or integration into an existing line, our solutions are fully adapted to your production goals. From concept to installation, we work closely with you to deliver performance, reliability, and flexibility.

Details

| Details | |

|---|---|

| Features & Benefits | All metal parts in stainless steel, Flexibility in container handling: quick and simple container size changeover with a unique pocket-like adjustable conveyor preset interchangeable lid and container denester heads, HMI user-friendly touch-screen: featuring status monitoring setup maintenance screens and production statistics for easy operation, NEMA 4X wash-down stainless steel control box ensuring safe operation in cold environments, PLC controlled system: ensuring precise control of each module for reliable and consistent performance, Reliable Pick and Place Unit for Lids & Containers Distribution, Safety & easy maintenance: the system automatically stops if no container arrives or if the lid denester head is jammed. simple open design for easy maintenance, True one-by-one lids & containers escapement system: ensuring individual dispensing of lids and containers for optimal alignment and packaging quality, Trustworthy air removing closing head: effectively removes air to ensure a secure and tight seal, Unique conveyor system to accommodate round/ square/ rectangular or oval containers, Up-to-date robot-like machine with modular functions: offering customizable functionality to meet specific needs |

| Option & Accesories | Automatic plastic film sealer (PL500), Bottom fill lifting device: Ideal for dry powder or ice cream filling this device helps prevent air entrapment and compacts the product during filling, Catcher system: buffers dry products to eliminate delays at the filling station, Cheese dicer: a block cutter or dicer for feta or similar cheeses ideal for precision portioning, Corrosion protection: additional protection against brine chlorides and acids is available for corrosive environments, Denester heads: available for different lid and container formats including special heads for buckets with handles, Filler & mixer options: available for specific filling needs (see DV/ DM/ and DVM series), In-line check weigher: for precise filling and to eject incorrect containers, Product containment system: a pneumatically actuated "hat" guides dry product down to the container preventing product bounce, Transfer pump(s) to feed the filler(s) (see the PV series) |

| Specifications | Speed: Up to 50 containers per minute for 5 lbs buckets for Dry and Viscous Products |