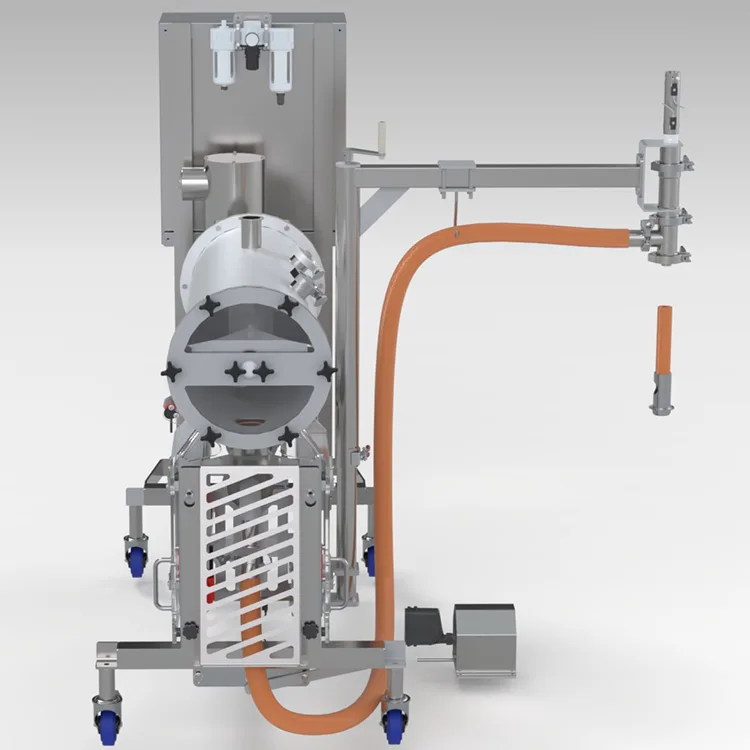

DVM1000 Soup & Salsa Volumetric Piston Filler with Agitator

The DVM1000 is an advanced Volumetric Piston Filler with a built-in mixing hopper, specifically designed for fresh food manufacturers. This machine ensures homogeneity in products that contain both liquid and solid components, such as chunky soups, vinaigrette, salsa, etc.

Perfect for a Wide Range of Products:

- Liquid & Semi-Viscous Products:

The DVM1000 is ideal for filling hot soups, sauces, vinaigrettes, and other liquid-based products with chunks, delivering precise and consistent fills every time. - Chunky & Solid-Containing Products:

Whether dealing with chunky soups or prepared salads with solid ingredients, the DVM1000 ensures that the chunks remain intact, without being cut or smashed.

Hot and Cold Product Capability:

The DVM1000 is versatile enough to handle both hot and cold products, making it a reliable solution for a wide range of filling applications.

Details

| Details | |

|---|---|

| Features & Benefits | Easy maintenance: easily accessible mechanical parts simple open design. On-screen error detection and diagnosis., Flexibility: simple and quick product changeover with a height-adjustable dispensing valve holder and a wide filling range enabled by an adjustable stopper inside the pneumatic cylinder, High accuracy in the filling process, High-speed performance, HMI user-friendly touch-screen: featuring status monitoring setup maintenance screens and production statistics for easy operation, NEMA 4X wash-down stainless steel control box ensuring safe operation in cold environments, PLC-controlled system: ensuring precise operation and easy integration into your production line, Safeguard product quality & integrity: seamless design / large diameter dispensing valve / all parts in contact with the product are made of stainless steel |

| Option & Accesories | Filling station for autonomous filler composed of: height-adjustable dispensing valve holder/ stainless steel table/ adjustable guides/ foot pedal, Level Sensor to control three product level in the hopper. Two levels control the feed pump. The third stops the depositor before air intake when product is low, Standalone Model Configuration: Includes a dedicated PLC and HMI for autonomous operation |

| Specifications | Speed: Up to 30 cycles per minute for 5 lb buckets, Speed: Up to 60 cycles per minute for 1 lb tubs |