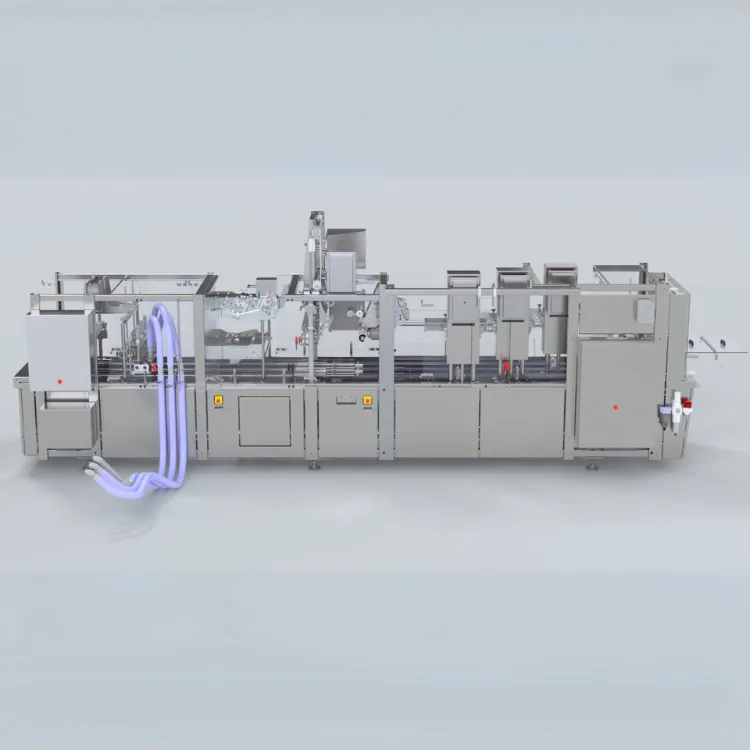

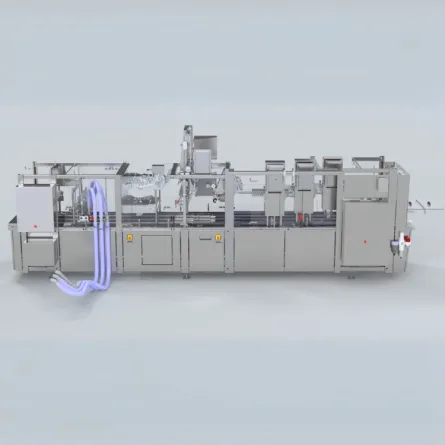

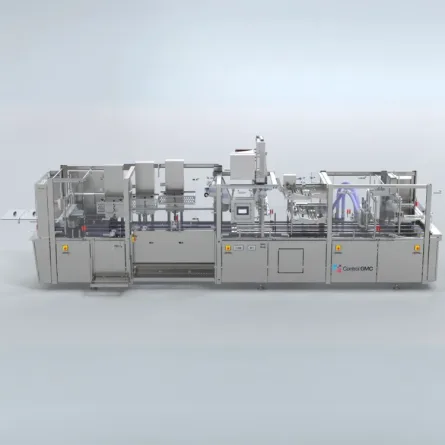

FDX6500 Triple-Lane Cup & Tub Filling and Sealing Line

The FDX6500 is a high-speed Triple-Lane Filling and Sealing Line built for large-scale production. It automatically indexes and fills cups, tubs, or buckets, applies film sealing with the PL500, then deposits lids or over-caps and closes containers ensuring seamless, high-volume packaging.

The FDX6500 can manage:

- Any Shape of Container:

Capable of filling round, square, rectangular or oval open-mouth containers. - Tamper-Evident & Non-Tamper-Evident Containers:

The system can fill and seal containers with or without tamper-evident features, ensuring secure and reliable packaging. - Triple-Lane System:

Designed for high-speed, high-volume filling with three lanes, allowing for optimized production and greater throughput. - Many Different Products:

Capable of handling liquid, semi-liquid, dry, viscous, or sticky products, making it suitable for various industries such as food, chemicals, and more.

We design and build custom-made machines tailored to your specific needs.

Whether you require a unique configuration, special features, or integration into an existing line, our solutions are fully adapted to your production goals. From concept to installation, we work closely with you to deliver performance, reliability, and flexibility.

Details

| Details | |

|---|---|

| Features & Benefits | All metal parts in stainless steel: provides long-lasting durability full washability and easy maintenance, Consistent closing head, Flexibility in container handling: quick and simple container size changeover with a unique pocket-like adjustable conveyor preset interchangeable lid and container denester heads, High cutting speed, High-speed performance, HMI user-friendly touch-screen, NEMA 4X wash-down stainless steel control box ensuring safe operation in cold environments, PLC-controlled system: ensuring precise operation and easy integration into your production line, Reliable pick and place unit for lids & containers distribution: guarantees accurate and efficient lid and container placement for smooth operation, Safety & easy maintenance: the system automatically stops if no container arrives or if the lid denester head is jammed. simple open design for easy maintenance, Seal pressure/ time and temperature are fully adjustable, True Three-by-Three Lids & Containers Escapement System, Trustworthy air removing closing head: effectively removes air to ensure a secure and tight seal, Unique conveyor system to accommodate round/ square/ rectangular or oval containers, Up-to-date robot-like machine with modular functions: offering customizable functionality to meet specific needs |

| Option & Accesories | Corrosion protection: additional protection against brine chlorides and acids is available for corrosive environments, Lane concentrator: to merge the two lanes into a single lane at the exit of the filling line, Special triple denester heads: designed for buckets with handles allowing for versatile packaging options, Transfer pump(s) to feed the filler(s) (see the PV series), Triple container lifting device: prevents air entrapment and compacts the product during filling, Triple denester heads: available for different lid and container formats, Triple fillers & mixers: available for specific filling needs (see DV/ DM/ and DVM series), Triple product catcher: buffers dry products to eliminate delays at the filling station, Triple product containment system: (Triple Hat): a pneumatically actuated "hat" guides dry product down to the container preventing spillage and product bounce |

| Specifications | Speed: Up to 108 containers per minute 1 lb tubs, Speed: Up to 90 containers per minute for 5 lb buckets |