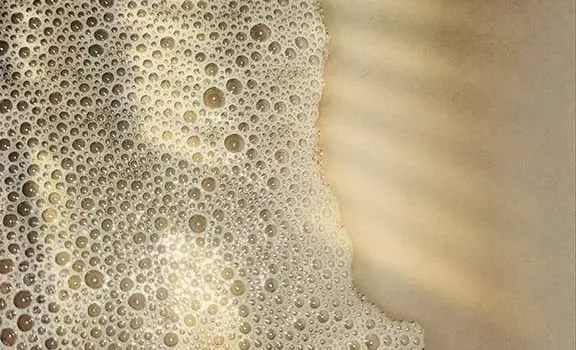

Foamy and/or Dangerous Liquid Products

Packaging machines for foamy and/or dangerous liquid products

Foamy or Hazardous Liquids Require Extra Care—We Deliver It

At Control GMC, we understand that packaging foamy or dangerous liquids isn’t just about accuracy—it’s about safety, control, and compliance. That’s why our equipment is specially engineered for the unique challenges these products present.

For foamy liquids, our bottom-fill technology ensures smooth, splash-free dosing while maintaining high speeds. When dealing with hazardous materials, our heavy-duty closing systems are built to handle industrial-grade containers, including UN-certified pails, with absolute reliability.

From small-scale batch production to high-volume industrial lines, our modular solutions adapt to your operation—offering the flexibility and performance you need to pack safely and confidently.

Let’s build a better way to package foamy and/or dangerous liquid products together.

Our packaging machines for foamy and/or dangerous liquid products

Discover how precision, safety and confidence meet performance in foamy or dangerous liquids packaging

Find the right machine for your foamy and/or dangerous liquid products

Frequently asked questions about foamy & hazardous liquid products packaging

Not sure which solution is right for your foamy and/or dangerous liquid products? These frequently asked questions will help you understand how our machines can fit your product and packaging needs.

Yes. We offer specialized closing equipment such as the FS1800-UN, designed specifically for UN-certified industrial pails. These machines ensure proper sealing, tamper evidence, and compliance with international safety standards.

Absolutely. Our modular lines are engineered to handle both hot and cold products. With temperature-resistant components and filling options, we offer safe, reliable performance across a wide product range.

Our systems are equipped with safety interlocks, sealed filling environments, and optional ventilation or extraction units to protect operators from exposure. Each design complies with industrial safety standards, ensuring secure handling throughout the packaging process.

We use bottom-up filling with controlled flow rates and programmable nozzles to reduce turbulence. The system automatically adjusts the fill speed and nozzle movement based on product viscosity and temperature, preventing foam buildup and overflow at high throughput.

Yes. Our filling, sealing, and closing modules — including the DM1000 and FS1800-UN — can be combined into a fully automated line. We also offer denesters, lid applicators, and conveyors to create a seamless, turnkey solution adapted to your production capacity.

Sauerkraut & Specialty Salads

Sauerkraut & Specialty Salads