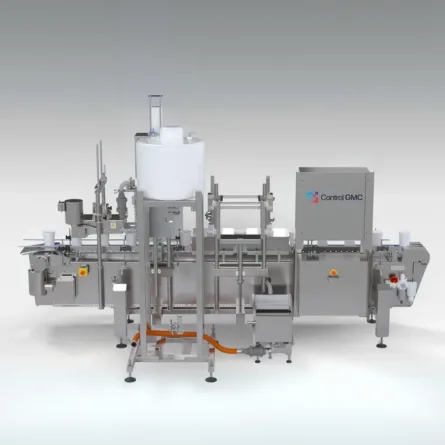

FDS1500 Automatic Cup Filling, Lidding & Closing Machine

The FDS1500 is a high-performance, hand-fed Filling, Lidding, and Closing Machine designed for cups, tubs, and buckets. Ideal for customers looking for cost-effective solutions or when containers are difficult to denest or prefill by hand with base products. This versatile machine ensures fast and precise filling and sealing.

The FDS1500 can manage:

- Any Size of Containers:

Round, square, oval and rectangular open-mouth containers: ensuring reliable, consistent filling and closing. - Any Shape of Containers:

Cup, tub and bucket containers: making it perfect for a wide range of applications across various industries. - Many Different Products :

This machine can fill liquid, dry, viscous, or sticky products, making it adaptable for various food and non-food industries.

We design and build custom-made machines tailored to your specific needs.

Whether you require a unique configuration, special features, or integration into an existing line, our solutions are fully adapted to your production goals. From concept to installation, we work closely with you to deliver performance, reliability, and flexibility.

Details

| Details | |

|---|---|

| Features & Benefits | Air removal closing head that ensures a tight seal with reliable performance, All metal parts in stainless steel: provides long-lasting durability full washability and easy maintenance, Flexibility: simple & quick container size changeover, High-speed performance, HMI user-friendly touch-screen: featuring status monitoring setup maintenance screens and production statistics for easy operation, NEMA 4X wash-down stainless steel control box ensuring safe operation in cold environments, PLC-controlled system: ensuring precise operation and easy integration into your production line, Reliable lids distribution using a true one-by-one lids escapement system to guarantee efficient and accurate lid application, Safety operation & easy maintenance |

| Option & Accesories | Conveyor extension to allow empty or full containers accumulation at the entry side of the equipment, Corrosion protection: additional protection against brine chlorides and acids is available for corrosive environments, Gating system: for containers arriving with no space between them, Multiple denester heads for different lid formats, Pneumatic closing head: for increased sealing efficiency |

| Specifications | Speed: Up to 40 containers per minute for 5 lb buckets for Liquid & Semi-Liquid Products, Speed: Up to 50 containers per minute for 1 lb tubs for Liquid & Semi-Liquid Products, Speed: Up to 60 containers per minute for 5 lb buckets for Dry & Viscous Products, Speed: Up to 70 containers per minute for 1 lb tubs for Dry & Viscous Products, Testing with actual samples is required to validate speed and performance criteria. |

Sauerkraut & Specialty Salads

Sauerkraut & Specialty Salads